In the operation of stoves and fireplaces, fire safety is considered a priority. Fireplace doors allow you to protect yourself from accidental sparks and coals that got into the room from the firebox. And if they regulate the intensity of fuel combustion and draft in stoves, then they are arranged in fireplaces to protect against fire. It should be visible, otherwise the essence of the hearth will disappear. Since it heats the room, and also makes it possible to admire the living fire.

Doors: construction

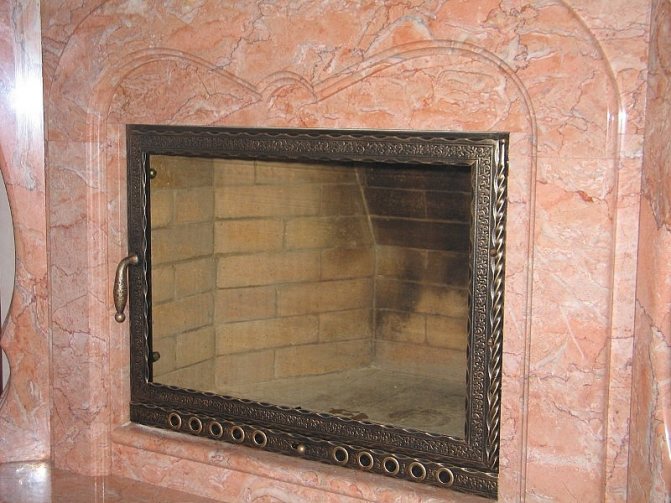

To create a panoramic effect, glass fireplace doors are used. The glass is surrounded by a metal frame around the perimeter, in which there is an insulation gasket. In fact, it is a transparent ceramic, therefore, it can withstand heating up to 800 ˚C. The configuration of the door depends on the style of the cabinet, while it occupies a large or the entire front area of the firebox.

Glass comes in different sizes: medium, small, large. In this case, geometric shapes are made as follows:

- rectangular;

- arched;

- trapezoidal;

- flat or convex;

- round, oval.

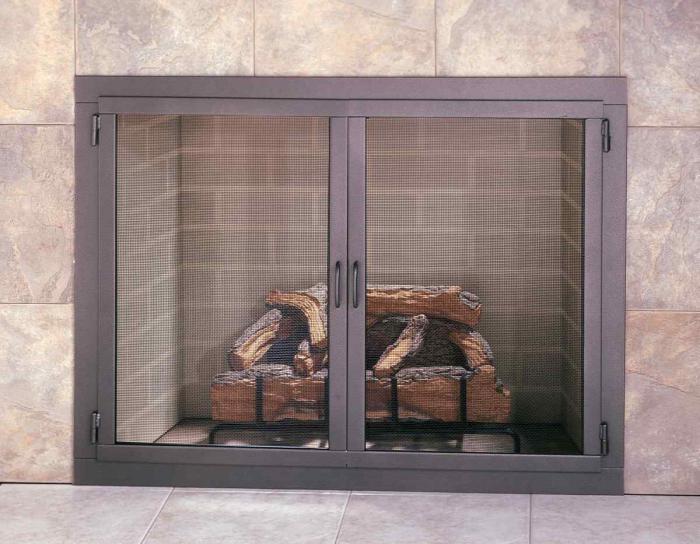

Closing the doors with glass is also possible in various versions. Among them, the most convenient:

- double hinged (two doors in the middle are connected, hung on the hinges on the sides);

- swing (one flap is on the side hinges);

- close up vertically.

Structurally, the doors for stoves and fireplaces can consist of one or more rigid parts connected to each other. Each of them is installed in the sash, pre-framed with a seal. Panoramic glasses are the most convenient for observing the flame. They are not divided into parts and are practically equal in area to the dimensions of the sash. A similar design is suitable for a large fireplace in a country house, which is equipped with a chimney structure.

Types of fireplace doors

The product classification depends on what material the doors are made of. There are several types with their positive and negative qualities, features of operation and installation.

Fireplace glass doors

Fireplace door with glass is a great solution for different interior styles. Fireplace heat-resistant glasses are resistant to high temperatures and have increased strength. The thermal expansion of the material is insignificant - the coefficient is 30 times less when compared with ordinary glass. Due to their high heat transfer, they are able to withstand heating up to +1000 degrees Celsius, while without cracking.

After 30 minutes of operation of the fireplace, the heating of the glass will be in the range of + 50-250 degrees Celsius. For hardened products, the temperature reaches +500 degrees.

Heat-resistant glasses are made from special raw materials on special equipment, practically without the use of impurities. The material is resistant to fire due to a special hardening technology, in addition, it is chemically treated and thermally polished.

Due to the above nuances, the manufactured products are in no way inferior to their metal counterparts. These glass fireplace doors are difficult to break or scratch.

Comment! Due to its high strength indicators, this material is often used to equip a floor protective screen near the hearth.

Fireplace doors made of heat-resistant glass are distinguished by:

- opening method;

- type of framing;

- design.

Modern technologies make it possible to decorate such products with multi-colored drawings and patterns.An original and effective solution - doors that open like a guillotine, they will perfectly fit into any interior. This makes it possible to use the heating unit both open and closed.

Advice! Due to the heavy weight of the structure, it is recommended to equip glass fireplace doors with an automatic opening mechanism. This is done for added protection against burns.

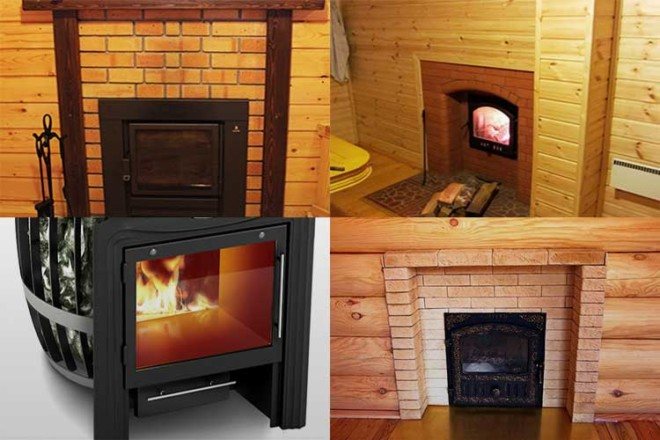

Steel fireplace doors

This category of doors is made entirely of metal. Installation of such structures is simple, they are able to retain thermal energy and at the same time have increased fire safety. Many owners of stoves and fireplaces choose iron doors, since they are not only reliable, but also functional. If desired, do-it-yourself metal doors, and the cost of work is minimal. However, factory samples of doors are also offered at an affordable price.

Metal doors for a fireplace have their own advantages:

- Availability. When compared with fire-resistant glass doors for fireplaces, metal counterparts are cheaper, which is why they are widespread. Most often, such a design can be found in baths and dachas, where practicality is put in the forefront, rather than aesthetics.

- Durable and durable with proper care. From time to time, metal fireplace doors need to be treated with heat-resistant paints to protect them from corrosion. Do not forget about cleaning the surface from soot and dust. Metal doors can last for several decades.

Important! Recently, one can observe a decline in popularity for metal doors, since they do not provide an opportunity to observe the playing flame.

Wrought iron doors

This variety is made from steel. As a rule, we are talking about the usual openwork grate, which decorates the fireplace in an original way. The key advantage is decorative characteristics. If you need to provide reliable protection from fire, then a forged door will not be the best assistant. To extend the service life of forged doors, manufacturers cover products with refractory enamel.

Most of the forged doors are made in the form of a lattice, decorated with various patterns and ornaments. There is little demand for them, since they are not able to fully fulfill their function: smoke passes through the holes, or a spark may fall out.

Most often they are installed in rooms decorated in a classical or baroque style. It all depends on how they are decorated - there are many beautiful photos of forged fireplace doors posted on the network.

Cast iron fireplace doors

Cast iron products are less popular than modern fireplace doors with fireproof glass. As stated by most manufacturers, this option is intermediate between glass and metal structures.

However, a cast iron door is much more resistant to temperature than a glass door. Negative trait - less attractive appearance. The weight of such a door can reach several tens of kilograms.

Important! Cast iron is characterized by physical wear and tear, therefore, due to the low durability of the material, it is practically not used for the production of fireplace doors.

Nevertheless, many buyers choose cast iron doors for their fireplaces.

Operation of doors

If your fireplace runs on wood, then soot begins to settle on its walls over time. The situation is aggravated by coniferous logs by the fact that they actively emit resin. On the walls, they settle in the form of soot. Consequently, fireplace doors become cloudy and dirty. To combat this phenomenon, a self-cleaning system has been created.

It is an air curtain created by the flow of air through the slot. It hits the upper part cold and goes down. Thus, the glass door does not need to be cleaned.

Wrought iron doors

It should be noted that the same requirements are now imposed on the materials of the shutters, regardless of the shape of the fireplace body. If it has an angular shape, and the sash is shaped, the metal can make up its main part. For this, cast iron or refractory steel is used, and glass in a similar version has the form of a stained-glass window. That makes it possible to combine glass with a variety of texture and tint.

The cast-iron fireplace door must always be closed to prevent further floor ignition. If a biofireplace is used (this is typical for an apartment), then it is made from the same materials: metal and glass ceramics. Fittings of various types of sashes usually include handles, which can be removable, hinged hinges, locking mechanisms, fasteners.

Manufacturing material

Despite the abundance of modern refractory materials, firebox doors are made of iron, cast iron or special grades of glass. In ancient times, ceramics were used for the manufacture of all structural elements of hearths. Cast iron and metal alloys began to be used for these purposes later, several centuries ago; heat-resistant glass is a relatively new representative in this series, gaining popularity at an accelerated pace.

Cast iron

Cast iron products for ovens have maximum durability, which exceeds the life of products made from other materials. The alloy is characterized by high-temperature properties, reliability, and wear resistance.

Cast iron doors can be safely installed on any furnace, even those in which it is planned to burn coal or coke, the high combustion temperature is not dangerous for them.

Nowadays, many consumers do not really like the design of doors for cast iron stoves; it is difficult to pour original products from this alloy, and the population wants to see not ordinary, but interesting interior details at home. The situation is somewhat brightened up by the presence of various models consisting of one or two sashes. Cast-iron doors look original, with a glass insert in the center, but the production of such models is not yet massive, they are much more expensive than conventional products.

On a note! It is important to consider that the installation of cast iron products on the furnace must be carried out by means of reliable fasteners, because the mass of the alloy is large and the load on the fasteners will be significant.

Steel

Stainless steel alloy doors are in great demand, especially for installation on ovens exposed to humid air, such as a bath.

Without damage to the integrity, the humid environment withstands the brick of the furnace walls, and the iron alloy, upon contact with water vapor, can prematurely begin to oxidize and break down. Therefore, to ensure durability, despite the higher price, the doors are made of stainless steel.

Such products are not very heavy, they can be easily inserted, securely fixed, and replaced if necessary; there are no increased requirements for fastening structures.

To ensure durability, oven doors made from common iron alloys, which are also found on the market, are periodically coated with heat-resistant paints.

Glass

Oven glass doors are the latest technology, although heat-resistant glasses have been known for a long time. They were used in chemical and metallurgical industries, were installed in some technical devices, equipment, for example, in muffles and thermostats.

For the mass consumer, these products have become available in recent decades, during this time, methods have been mastered to obtain several types of glass products that are resistant to high temperatures.

There are glasses of one or more layers that can withstand different heating temperatures.Single-layer sheets with a thickness of up to 3 mm can withstand the combustion of wood, plant waste, peat, animal waste in the furnace. With multilayer sheets with a minimum thickness of 4 mm, you can safely cover stoves intended for burning coal; thick fireproof glass will withstand high temperatures without cracking, deformation, destruction.

Glass doors offered for sale may look as follows:

- transparent;

- matte;

- raised.

The manufacturing technology determines the cost of products, which in any case exceeds the financial costs for the purchase of metal products.

Glass products must be regularly looked after using conventional means, for example, "Mister Muscle", otherwise the main advantage - the ability to observe the hearth - will be impossible to evaluate.

If you don't really want to wipe the glass every time before melting, you can buy special glass doors, the surface of which is covered with special substances that remove soot. Then no effort will be required from the owners; when heated, the surface will clean itself, the soot will simply burn out without leaving a trace.

When purchasing glass doors for installation in an oven, it is imperative to look at the technical data sheet, to clarify the permissible operating mode in order to prevent troubles during use. The range of modern products is wide, the range of permissible loads varies for each type of glass, so it is important to clarify all the characteristics in advance.

Metal door

Today it is very common to see fireplaces, the doors of which are made of thermal glass. The first do-it-yourself fireplace door was made of metal. The difference between such structures is that they could not be integral. An important feature is also the shape of the doors. The point in this case is that the fireplace was able to heat the room solely due to thermal radiation, which required an open hearth.

The advantages of metal doors include their visual appeal. There are several disadvantages. In such doors, there is practically no protection against the resulting smoke. In addition, they will obscure the view of the fire, thereby depriving it of its special charm. Fireproof metal fireplace doors also differ from others in that they prevent heat radiation. And this is not particularly welcomed by the owners of the house. Although the doors do not interfere very much, since the metal can heat up and then give off a little heat to the room.

DIY making

Not many people know that you can make fireplace glass doors with your own hands at home. You do not need to have certain skills for this. All that is needed to perform such work is the presence of a special tool that will allow you to work with glass and metal, as well as a welding machine.

At the first stage, you will need to make a detailed drawing, according to which you can determine the shape, size, style and other important parameters of this element. After that, you need to make a calculation and buy materials, fittings and components for assembling fireplace doors.

As a base or otherwise - a frame, we use a steel or cast-iron frame, which is assembled from a certain number of sidewalls, each of which is connected by welding. In the center of the frame, glass is installed, selected and previously cut to size. It is also a position to be well secured!

We choose only refractory, tempered glass, which tolerates strong heat well. Since working with glass is very difficult and painstaking, having determined the required size, you can take it to the workshop. It will be inexpensive and you will get a guaranteed positive result!

Next, we fix the handle, it is important that it is comfortable and also made of refractory materials, stainless steel. The last step is to fix the glass door to the fireplace itself. This is done using special hinges and fasteners. It is important that they are able to withstand the weight of the sash well and have refractory properties.

Thus, now you can decide for yourself what is better to buy doors with glass for a fireplace or make from home with your own hands from scrap materials. In any case, remember that a hermetically sealed firebox is a guarantee of safe use, protection against accidental fire, coal and sparks entering the room.

In this video, you can learn more about how do-it-yourself doors with glass are made:

Glass fireplace doors

Glass is a very fashionable material today. It became widespread in the twentieth century. And the appearance of fire-resistant glass completely changed the views on the design of the fireplace. This new material made it possible to observe the flames. In addition, it became possible to control the combustion, supplement it, change it without checking each time by constantly opening the doors.

Among the glass fireboxes, you can see facades of different nature: convex, prismatic, angular, three- and two-sided - whatever the consumer chooses. They will not hide the flame from the eyes at all, but quite the opposite - they can increase the viewing angle.

Fireplace door - do it yourself

When you decide to install a fire door right at the stage of building a fireplace, this process will go completely unnoticed for you - the brickwork will be immediately adapted to the door. However, when the fireplace was built several years ago, and you decided to do this simple, at first glance, task, then there will be much more trouble. In order for the fireplace door to be installed with your own hands without unnecessary monotonous labor, you will need tools such as a grinder equipped with a ceramic cut-off wheel, a building level, a heat-resistant oven mixture, ceramic dowels and screws, asbestos thread.

Strained glass

It is made from simple glass by tempering: it is heated to a temperature that causes softening, after which it is very quickly cooled. Due to such painstaking work, glass is able to acquire the characteristics that are necessary. Resistance to high temperatures (400 degrees) appears. In addition, along with this parameter, resistance to various mechanical damage arises. This figure is 2.5 times higher than that of a simple glass coating.

Requirements for materials

For fireplace doors, high-strength and heat-resistant thermal glass is used, which has undergone special hardening and processing. It can withstand up to 10,000 C for several thousand hours of direct use.

This glass contains elements such as heat-resistant quartz, transparent crystal ceramics. The most popular is quartz glass, as it has the smallest expansion when heated. In terms of its strength, such material is not inferior even to metal products. The use of ordinary thermal glass (for the sake of economy) is impractical, since it cannot withstand temperatures above 1500 C and may crack at the first use.

Glass can be of various sizes, depending on the parameters of the fireplace, various geometric shapes and curvature.

It is possible to use tinted glass, which will dim the bright light of the flame. Installed double or laminated glass will contribute to even safer use.

When choosing a glass, it is necessary to consider:

- heat resistance, paying attention to the type of fuel;

- lifetime,

- the thickness of the glass screen (not less than 3.5 - 4mm).

Refractory glass has a drawback: it is quite heavy

... This must be taken into account when choosing the fastening of the doors and the methods of their functioning, creating the most comfortable conditions for handling this device.

Quartz glass

It is made from silica (quartz or sand), not glass. Other impurities are not added at all, or at a minimum. Such glass has the most elementary composition, but the production technology is highly complex. It has a very high melting point, which makes it difficult to process and process. But today it is increasingly used in the manufacture of fireplace doors. It is thanks to the high efforts that were put into production that this glass has a high price, being considered one of the most expensive.

Should I put the door on the fireplace? The advantages of an open fireplace.

More specifically, an open fireplace is a very practical thing. Whether it is a house with or without stove heating. Yes, let's just say that stove heating does not exclude the presence of an additional fireplace. It perfectly complements everyday life in a house with stove heating. With a fireplace, it is much easier to choose the mode of heating the stove for heating the house, we will talk about this in more detail later.

A familiar picture: a family gathers and two or three generations are sitting at their smartphones ... believe me, a fireplace can turn a familiar picture a little. It acts as a gathering place. He participates in life - as an occasion for fellows, as a small holiday. A little fireworks, if you like analogies. Living fire carries something magical ... Be that as it may, it fascinates, disposes to communication. Draws attention away from the smartphone. Living fire in our life is something unusual, oddly enough.

It is even possible to hold business meetings behind an open fireplace, not just family ones. It would seem why put a fireplace door with glass?

Borosilicate glass

This glass is made from a large amount of silica with the obligatory addition of boron oxide. This chemical element is famous for being able to provide a low melting point, which means that the glass will have plasticity. The finished product is capable of having a high degree of heat resistance (about 800 degrees). In addition, it will be endowed with a special mechanical strength, 5 times higher than that of ordinary glass. That is why fireplace doors are so often made from it.

Glass fireplace door: pros and cons

Fireplaces in private houses perform not so much a heating function as a decorative function, creating an impression of coziness and home warmth among the owners and guests. In order to achieve this effect, the fire must be visible, but an open firebox is unsafe in terms of fire hazard.

This problem is solved in only one way - by installing it on the fireplace insert glass door (option combined with metal is possible). It is also worth noting here that it will prevent smoke and soot from entering the room. Glass doors easy to clean, but sometimes you have to do it all the time. With a specially thought-out design, cleaning is not required.

Advantages of a glass fire door

- achieving the required level of fire safety;

- relative fuel economy due to slower combustion and reduce heat loss;

- using the fireplace as an additional source of heating;

- preventing carbon monoxide from entering the room;

- many options for decorative arrangement of the door by inserting metal curly and patterned elements while maintaining the view of an open fire.

Disadvantages of a glass door

- Smoked glass

- Lack of clear sound crackling firewood

- High temperature of the firebox

- Additional fire safety

- Expensive manufacturing price (20-25 tr.)

- Lack of the very feeling of a fireplace

If the door is of poor quality (equipped with glass of low quality heat resistance), then it will explode with negative consequences for people and the premises.

Positive qualities are also present in other types of doors for fireplace inserts (metal, refractory ceramic, cast iron), but they need periodic cleaning of the scale. In addition, they do not provide complete protection against the ingress of harmful elements formed during combustion into the room, they heat up to a dangerous temperature and exclude the possibility of observing the fire.

Types of glass for the fire door

- Tempered. Made by tempering standard glass. Withstands temperatures up to 400 ° C and is resistant to mechanical damage, including shock. This type of glass is easy to manufacture and relatively inexpensive.

- Borosilicate. Glass is made with the addition of boron oxide; it melts at relatively low temperatures. The heat resistance of the material reaches 800 ° C, and the strength is twice the level of tempered glass. Thanks to these qualities, this material has gained convincing popularity even at a relatively high price.

- Quartz. Quartz glass differs from borosilicate glass with good transparency, but the cost is off scale due to the complex production technology.

The technology of self-installation of a glass furnace door

Preparatory stage

First of all, the required door size is determined. The larger it is, the heavier, the load on the load-bearing parts of the fireplace is higher. If the single door becomes too heavy for the existing size of the furnace hole, you will have to install a double door. Remove glass from the door to avoid accidental damage during fitting and installation work.

Next, a dirty and not very healthy part of the work is done - grooves (grooves) for the door are made around the perimeter of the furnace hole with the help of a grinder or manually. During this operation, the resulting seam must be measured horizontally and vertically using a building level. Depth and width are determined by constant fitting of the door frame for tightness and sufficiency of entry into the groove. In addition, when determining the depth of the joint, take into account the space for the spacer.

Door installation

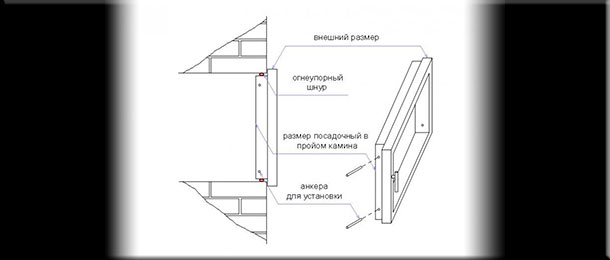

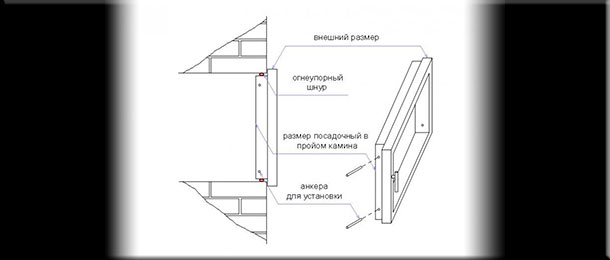

The perimeter door is wrapped in 2-3 layers of asbestos cord impregnated with a special heat-resistant mortar for oven masonry. Then it is inserted into the opening and additionally attached to it on special devices (dowels for ceramics).

After installation, the junction of the frame to the combustion hole is checked for cracks and irregularities. If any are found, they are sealed with a solution (refractory sealant) and, if necessary, with an asbestos cord. The mortar for masonry is suitable for use, where the TV is for 30 minutes, therefore, with large door sizes or installing a structure from several parts, this circumstance must also be taken into account.

Final work

After the mixture has completely set at the joints (up to 4 days), glass is installed in the door and a check is made for the operation of the fireplace when fuel is burning in it. The identified imperfections (uneven burning or smoke entering the room) are eliminated, and the fireplace is ready for final cladding.

In the article, you learned how to equip an open fireplace with your own hands. glass door, and step-by-step technology of work.

Fireplace glass door

Making doors

These works are not very difficult, therefore, they can also be performed by a non-professional. You do not need specific skills and knowledge. Production takes place in this order:

- According to the required parameters, a corner is cut out, which is laid out on an absolutely flat surface. Then it is inserted into the mold.

- The uniformity and correctness of the connections is checked using a square.

- The joints of the elements are fixed to each other by welding.

- Residues of welding are cleaned.

- A frame is installed on a metal sheet, and door contour marks are also made on the sheet.

- If the metal is about 2mm thick, then you don't need to weld a separate frame. Now its size is drawn - a little more than the internal one. The sheet will overlap, so it can protect the room from smoke.

- The metal element is cut with a cutting wheel and a grinder.

- The curtains are welded to the frame, after which a pre-prepared element is exposed. Then the accuracy of the placement of the curtains is checked, as well as their further tacking to the metal.

- The weld rush is removed, after which the handle is attached.

Now it is clear that it is quite possible to make a door with your own hands. Anyone can make this product. At the same time, it can be operated for a very long time.

Summing up, it can be noted that any type of doors is good in its own way. Materials for fireplaces are selected depending on the conditions of their operation. Consequently, this is the responsibility of the fireplace manufacturer.

The ideal fireplace door with glass, where can I get it?

If you need not just a door, but a fireplace with a heating function, then read our article on Zen (not yet on the blog) about fireplace inserts: Cons and advantages of a fireplace insert for heating. Modern models, analysis and comparison.

Below I will tell you about where to get the best, best fireplace door in the world. No, I don't do them ...